MVX

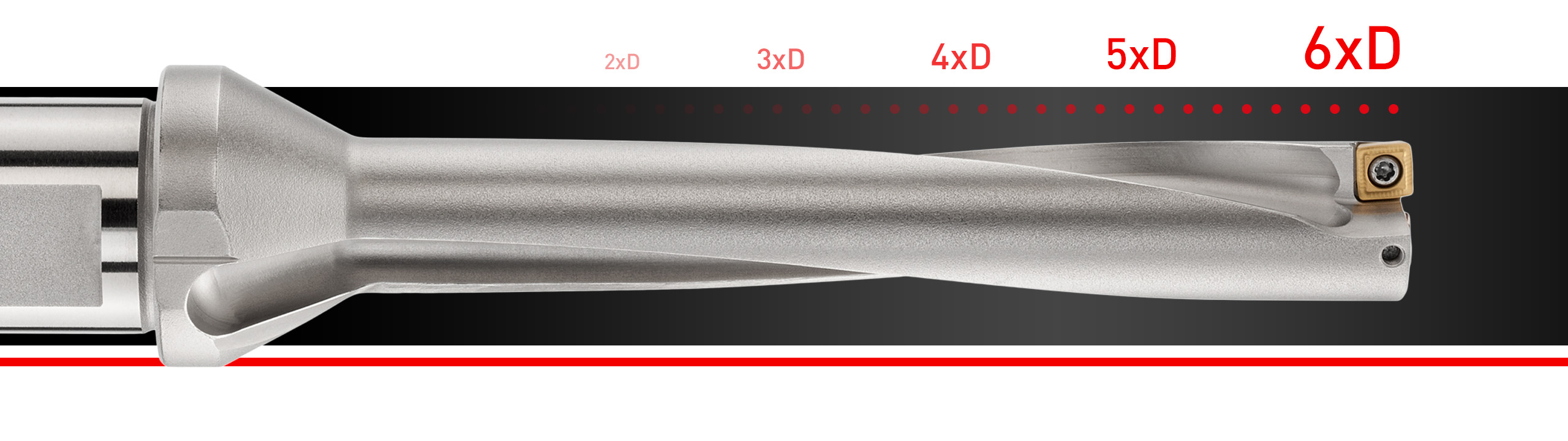

Indexable Drill for Drilling Depth up to 6xD

- Economical insert with 4 cutting edges

- Strong body for high performance drilling

- One insert type for external and internal pocket

Increased performance and maximised drilling depth up to 6xD

The MVX high performance indexable insert drill has an exclusively robust body with through coolant holes. The inner and outer inserts are interchangeable PVD and CVD coated types with 4 cutting edges. In addition to standard holes, MVX has been specifically developed to accurately penetrate partially angled surfaces. The unique wavy chipbreaker design of the inserts provide optimised chip control across various hole depths from 2xD and 3xD up to 6xD. The innovative MIRACLE SIGMA coating substrate offers superior tool life and an excellent resistance to chip welding at high speeds and feeds. This smart technology synergy offers process reliability and increased levels of productivity and ensures the MVX drill is ideal for the high performance machining of steels, stainless steels and cast iron.

4 cutting edges

Economical 4-corner insert.

Unique breaker design

A unique wavy design is used for the chipbreaker. This gives excellent chip control when machining steels, stainless steels and cast iron.

Wiper cutting edge

The wiper geometry for the peripheral cutting edge achieves excellent wall accuracy.

Ideal combination of outer wear resistant grade and inner tough grade insert.

A highly wear resistant CVD coated insert is used for the peripheral edge and a PVD coated insert is used for the inner position for extra stability.

High rigidity body

Increased surface hardness prevents abrasive damage caused by chip flow. Optimum insert position controls deformation and vibration of the holder. This enables a maximum drilling depth of L/D=6.