MTEC

Mitsubishi Materials Technology Education Centre

Industries are rapidly evolving, and market requirements are growing at the same pace; better service, future-proof technologies, highly advanced turnkey solutions. Mitsubishi Materials has responded to increased customer needs by establishing MTEC facilities across the globe.

The facilities accommodate international teams of cutting tool experts specialised in project analysis, tool design and testing, through to the final solution implementation. The highly competent application engineers explore new machining paths and develop bigger ideas in close cooperation with customers, embracing technology transfer and open innovation. MTEC is the place where ideas become solutions.

Building on synergies that strengthen the collaborative framework with customers, machine tool builders and engineering professionals, the MTEC facilities now offer sophisticated technical solutions centres for the metal working industry.

Mitsubishi Materials operates two MTEC facilities in Europe; MTEC Stuttgart and MTEC Valencia.

CUTTING TRIALS

A COMPREHENSIVE APPROACH

Today, customers expect advanced end-to-end tooling solutions that can be readily deployed into their existing machining processes.

The highly experienced engineers in MTEC offer complete machining concepts that accelerate the speed to market while keeping a low cost-performance ratio. A thorough consultation with customers to identify the specific needs is the first step that defines the project approach.

MTECs house the latest high technology turning, milling and Swiss type machine tools, including 5-axis capability.

The machines are complemented by advanced coordinate measuring and quality inspection devices, together with the latest in tool setting equipment.

This enables engineers to test in-house the viability of the solutions in the workplace.

- Fully customised high-end solutions

- Easier and faster deployment into existing manufacturing processes

- Complete solutions from a single source

- Maximised speed to market

BENEFITS

PROJECT ENGINEERING

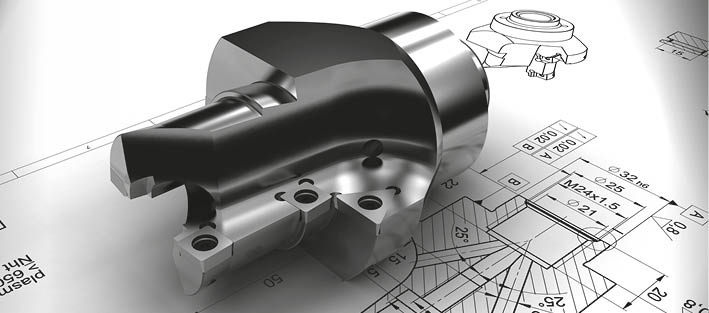

CUSTOMISED TOOLING SOLUTIONS

Mitsubishi Materials has established a specialised European project engineering team in MTEC Stuttgart, consisting of highly skilled designers, engineers and project managers that provide customers with various services.

Whether it is for bespoke tool designs, special tool development, tool modifications and CAD/CAM programming, or evaluating machining simulations, the project engineering team can meet these needs.

For improved accessibility for customers and support from the MTEC facility, project engineering professionals are located in sales offices across Europe.

Through constant communication and exchange of technological progress, the highest quality and sustainability of the solutions is ensured.

A broad network of international application engineers support the project engineering team, providing them with best practice insights, case studies and industry know-how.

- Tailor-made tooling solutions for all projects

- Competence via a broad project engineering network

- Increased flexibility and efficiency

- Solutions easily scalable to global projects

BENEFITS

PROCESS OPTIMISATION

ENGINEERING FOR ULTIMATE PERFORMANCE

Application performance control resulting in significant savings is one of the most common requirements demanded by customers today. As part of its core service portfolio, MTEC offers evaluation and optimisation of applied machining processes.

The first step is to thoroughly monitor the complete machining cycle and understand the individual needs of the specific application.

This evaluation includes a comprehensive review of all existing workflows, including cycle time and machining strategy, profitability calculations and risk management. Ultimately these processes also have the aim of delivering high quality and precision to the component.

Process optimisation solutions provide customers with new opportunities to enhance efficiency and productivity, triggering innovation and creating new machining perspectives.

- Significant cost savings

- Increased efficiency and productivity

- Improved utilisation of infrastructure and resources

- Reduction of the total number of processes

- Higher precision and overall quality

BENEFITS

COLLABORATION

BUILDING SYNERGIES

The engineers at MTEC go beyond the traditional customer-supplier relationship by working closely together with machine tool builders and other industry experts and professionals.

Synergies and mutual engagement with partnerships built over years ensures that they are based on trust and mutual respect for each others area of expertise.

This commitment and dedication to each project, helps to solve problems and find solutions. The sharing of information and results ensures resources and responsibilities are used efficiently, leading to long term knowledge gains for all parties.

Concurrent engineering, joint development, technology transfer and open innovation creates new avenues of opportunity, accelerating sustainable growth for all involved.

- Know-how and capability sharing

- Solution optimisation through joint development

- New perspectives for problem solving and innovation

- Increased efficiency, reduced risks single source

BENEFITS

EDUCATION

EXPANDING EXPERTISE IN THE LATEST TECHNOLOGIES

MTEC has been established as Mitsubishi’s advanced education, training and conference centre where theory and practice come together.

European customers can benefit from an extensive knowledge built over years of experience in the metal cutting industry. This experience provides comprehensive trainings, seminars and conferences, technical discussion forums and tool demonstrations.

The centre has been built on the principles of excellence for educational institutions, with emphasis on interactive learning, agility and adaptability, plus a high level of expertise and technological expectations.

MTEC‘s connectivity with Mitsubishi‘s other global technical and education centres ensures fluidity of information and global knowledge sharing capabilities.

- Training on the latest technology and tools

- Combination of theory and practice

- Networking with industry experts

- Global connectivity provides synergies of knowledge and information flow