IMX

Exchangeable End Mill System

- Ecological and flexible high performance milling

- Heads for Steel, stainless Steel, Aluminum and Super Alloys

- Excellent in long overhang milling

Smart milling for high end use

The exchangeable end mill system IMX is one of the most innovative and flexible solutions and was developed to cater for a wide application area. The smart combination of the solid carbide screw-in heads, offered in 12 different geometries, and the solid carbide holders offers the highest levels of precision, stability and productivity levels, especially for deep pocketing and long overhang applications. The exchangeable heads have the latest MIRACLE SIGMA coating that offers a higher wear resistance and the maximum level of tool life for machining titanium alloys, stainless steels and other difficult to cut materials. Geometries are also available for machining carbon and hardened steels as well as aluminium alloys. The holders and selected head types have through coolant capability ensuring optimum chip removal and cooling.

IMX – Exchangeable Head End Mills

A World First* in Tooling – Carbide Head and Carbide Holder

The IMX series is a revolutionary end mill system that combines the advantages of both solid carbide and indexable end mills.

The world first* feature of the carbide head and carbide holder enables security and rigidity close to that of a solid type end mill. This is made possible because the taper and end clamping faces of the head and the holder, are both solid carbide, only the threaded part is composed of steel. Benefits of this secure and accurate clamping method when compared to the usual steel to carbide method are greater efficiency from increased cutting parameters, improved accuracy and the all important factor of reliability.

Other tools with a carbide head to a carbide clamping section are usually constructed with a part carbide section brazed to a steel shank. This method has inherent weaknesses at the joint when compared to a solid carbide shank.

The IMX exchangeable series of end mills has obvious advantages for reducing inventory levels and tool change times. Additionally they are capable of high performance over a wide variety of applications. The primary application area is the machining of titanium alloys and heat resistant alloys such as Inconel. Furthermore, high performance milling of stainless steels, carbon and alloy steels and hardened steels is also a standard area of application. Each head type has irregular helix flutes for vibration control and the 4 flute corner radius type incorporates through coolant holes.

This wide variety of applications is made possible not just by the strong and reliable clamping system, but by the new Smart Miracle coated carbide grade EP7020. The super fine, super hard carbide substrate has a newly developed (Al, Cr)N Smart Miracle coating that can deliver substantially better wear resistance. The surface of the coating has also been given a smoothening treatment, resulting in better machined surfaces, reduced cutting resistance and improved chip discharge. This next generation Smart Miracle coating delivers class leading performance and tool life especially when machining stainless steels and other difficult-to-cut materials.

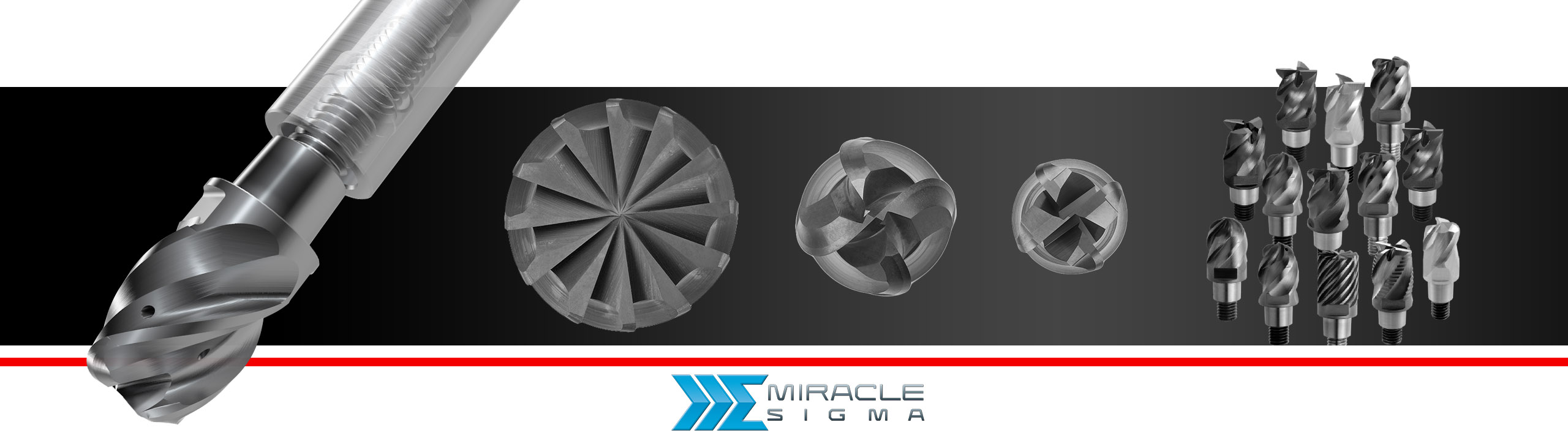

IMX heads are supplied in 5 different geometries

4 flute corner radius - with through coolant - Ø10 - Ø25, with irregular helix for vibration control

4 flute corner radius - Ø10 - Ø25, with irregular helix for vibration control

6, 10 & 12 flute - Ø10 - Ø25 for finishing, with irregular helix for vibration control

4 flute ball nose - Ø10 - Ø25, with irregular helix for vibration control

6 flute ball nose - Ø10 - Ø25, with irregular helix for vibration control

* According to our Research